Adsorbents

Natural Gas Treatment

BASF Natural Gas experts have a diverse portfolio of products to custom design a solution and help you meet your Natural Gas treatment needs.

BASF has been serving the natural gas treatment market for over 60 years. The Sorbead portfolio is used for the simultaneous removal of water and heavy hydrocarbons for pipeline transportation and underground storage of natural gas. BASF has extended this knowledge and expertise to serve the LNG pre-treatment market with its Durasorb® portfolio.

Why BASF?

Durasorb® is BASF’s innovation platform for the LNG industry and a custom-tailored solution that combines superior adsorbents with BASF’s expert designs.

Natural gas experts use proprietary design software to model the performance of the adsorbents in all parts of the vessel and optimize the temperature swing adsorption process. Based on the design calculations, BASF natural gas experts choose the ideal combination of adsorbents from the comprehensive BASF portfolio. The resulting installation ensures more efficient removal of contaminants, increases feed gas flexibility, and extends unit lifetime.

Portfolio of Products

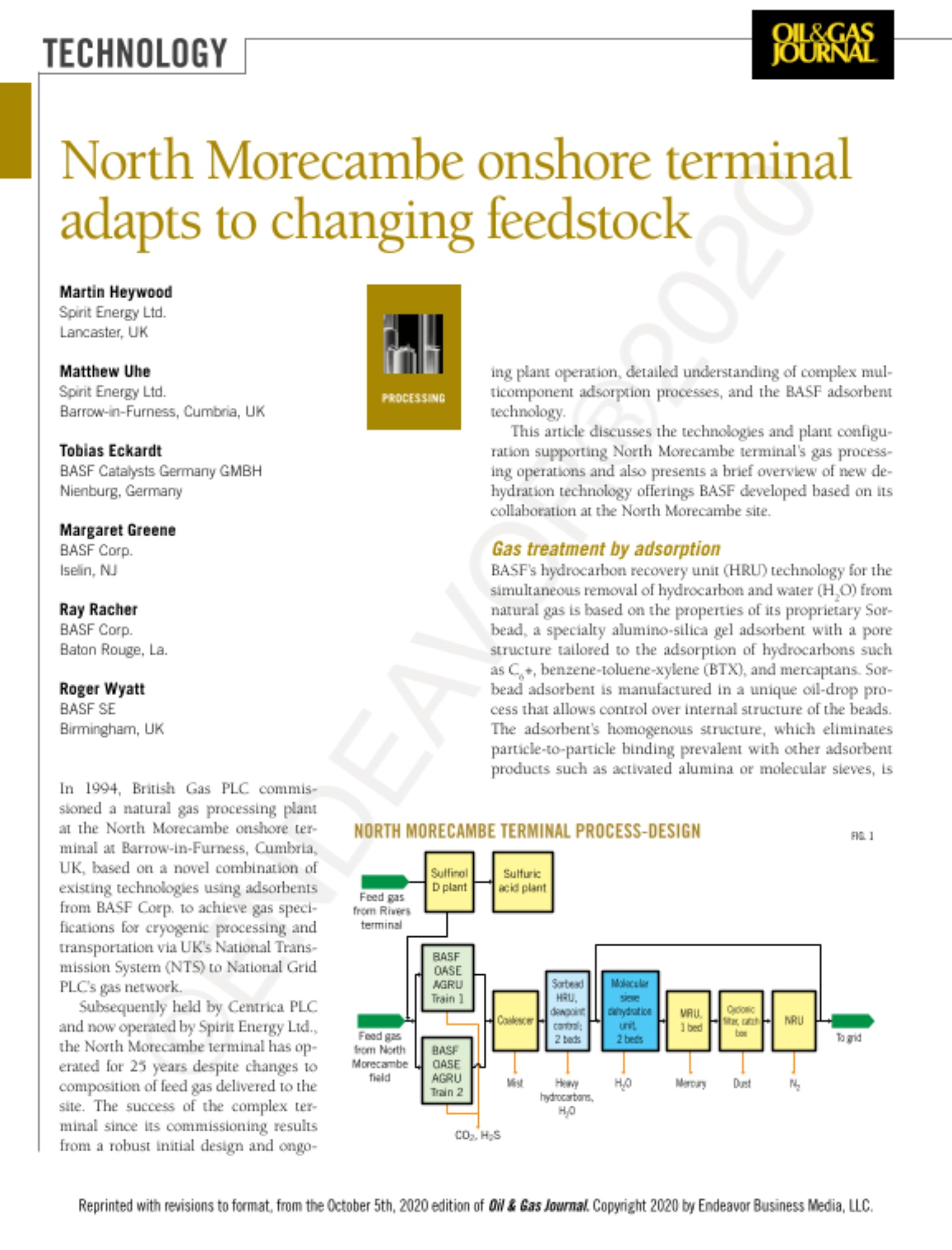

BASF provides the full LNG pre-treatment package with its Durasorb® and OASE Gas Treatment technology.

Innovative products and technologies solve problems at the plant by removing impurities and providing reflux resistance to increase unit lifetime. Depending on the gas feed conditions, the HRU and Dehy unit can be combined into a single unit, Durasorb® LNG MAX, capable of removing heavy hydrocarbons and water to cryogenic specifications.

Support and Services

BASF supports its customers in the design and operation of temperature swing adsorption units for gas treatment plants.

BASF technical experts provide process design, modeling, and basic engineering. In addition, BASF provides a range of technical services such as debottlenecking and process optimization, troubleshooting and revamps, analytics, and training. BASF tailored solutions address customer specific gas compositions, while considering the CapEx and OpEx priorities of our customers.

Publications

Results: 7

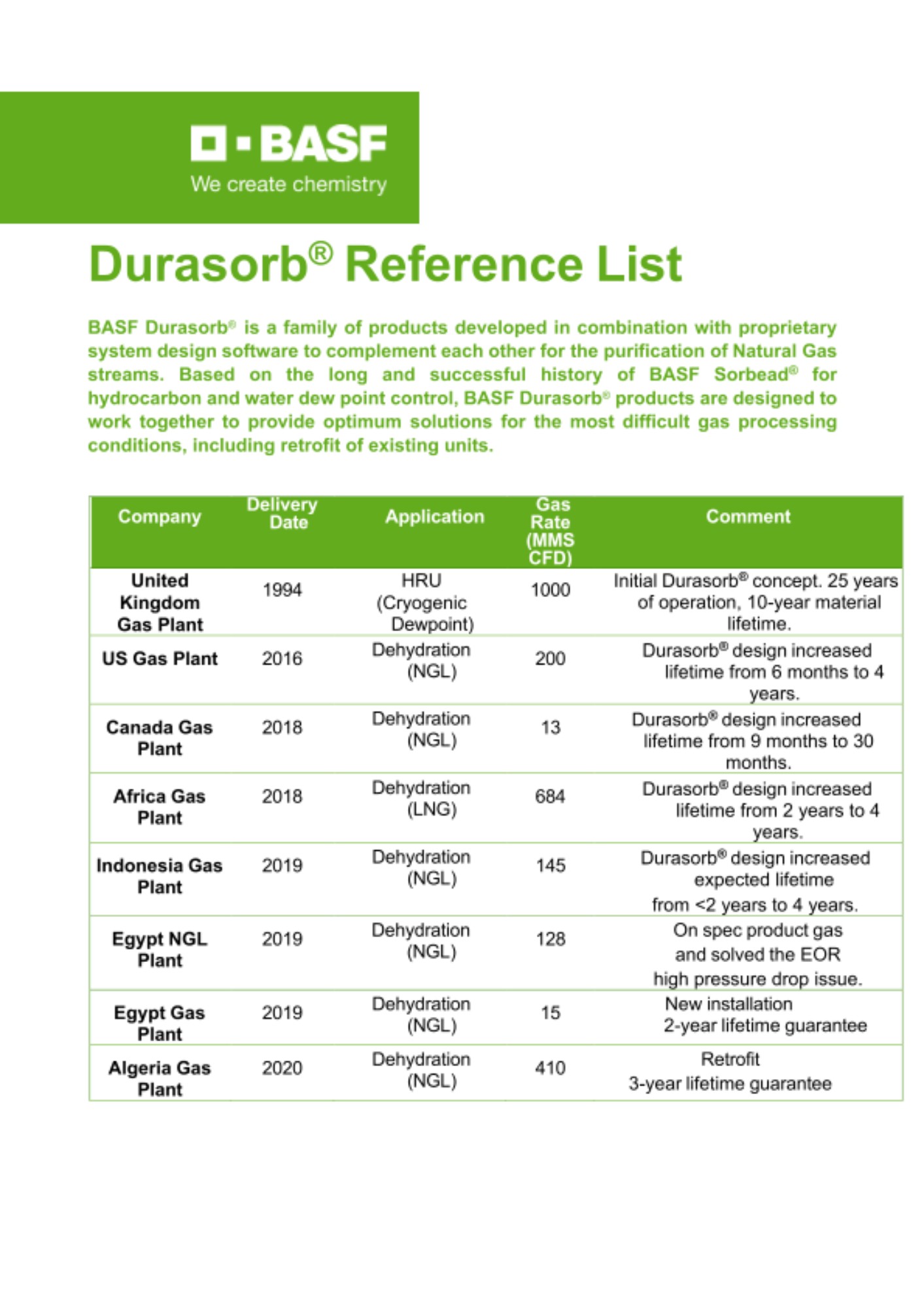

Durasorb® Reference List 2026

The solution to cold box freezing (LNG Industry Magazine, 2023)

Innovation in Dehydration (LNG Industry Magazine, 2022)

Coming out of the Ice Age (LNG Industry Magazine, 2021)

North Morecambe onshore terminal adapts to changing feedstocks (Oil and Gas Journal, 2020)

News

ExxonMobil awards BASF Durasorb™ Cryo-HRU with technology qualification for LNG pre-treatment