Adsorbents

Durasorb® HG

Durasorb® HG is a high capacity, robust mercury adsorbent designed to operate in the harshest conditions

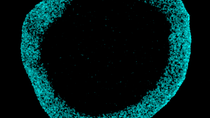

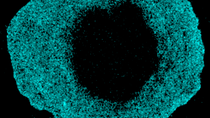

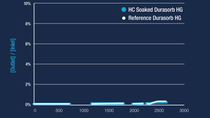

Durasorb® HG is a sulfided metal oxide adsorbent installed upstream in the LNG pre-treatment train to protect downstream equipment and materials from mercury contamination. Durasorb® HG has improved capacity and fast kinetics due to the optimal pore distribution, which allows fast diffusion of mercury into the core of the sphere.

Product Performance

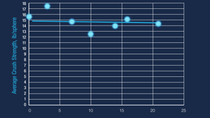

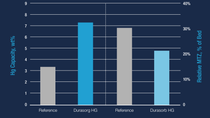

SEM images show increased mercury penetration for Durasorb® HG compared to reference sample. These results highlight the improved efficiency of Durasorb® HG.

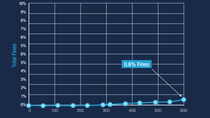

Lab test results show the unmatched material integrity of Durasorb® HG.

Durasorb® HG is easily removed from the vessel at the end of life due to material robustness. No loss of crush strength or fines generation in the presence of liquid water means no caking, no extreme techniques required for removal.

Support and Services

BASF supports its customers in the design and operation of temperature swing adsorption units for gas treatment plants.

BASF technical experts provide process design, modeling, and basic engineering. In addition, BASF provides a range of technical services such as debottlenecking and process optimization, troubleshooting and revamps, analytics, and training. BASF tailored solutions address customer specific gas compositions, while considering the CapEx and OpEx priorities of our customers.

Publications

Results: 7

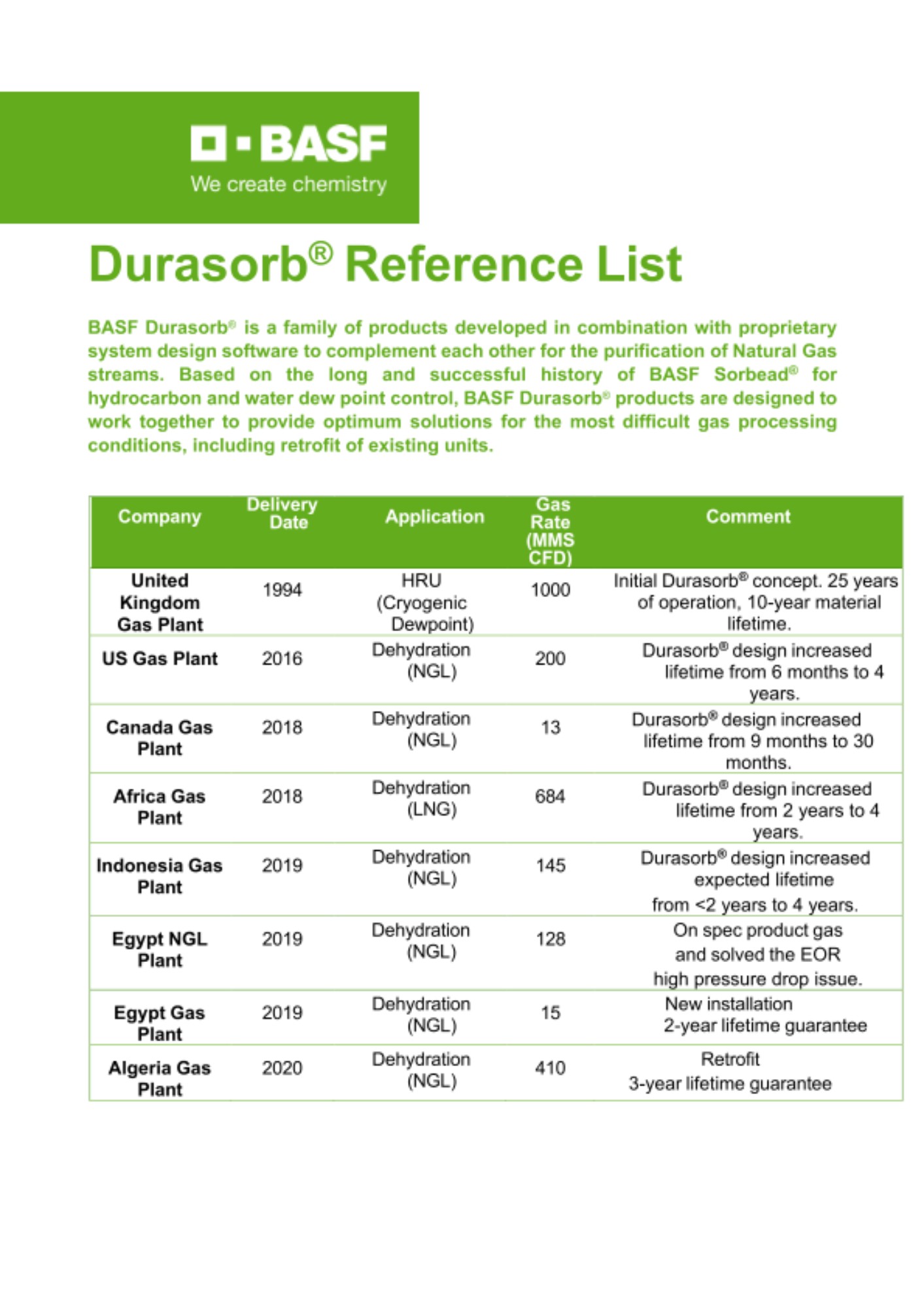

Durasorb® Reference List 2026

The solution to cold box freezing (LNG Industry Magazine, 2023)

Innovation in Dehydration (LNG Industry Magazine, 2022)

Coming out of the Ice Age (LNG Industry Magazine, 2021)