Adsorbents

Struggling to remove mercaptans and keep project costs in line? Time to consider Durasorb® LNG MAX!

Durasorb® LNG MAX offers a proven alternative to conventional approaches

Natural gas feeds containing mercaptans present a unique challenge to LNG producers: Conventional approaches to remove mercaptans from gas feeds are expensive, inefficient, and require additional units or equipment, resulting in higher CapEx and OpEx for the plant. I would like to show you how BASF’s Durasorb® LNG MAX simplifies the removal of mercaptans from natural gas and reduces costs.

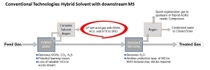

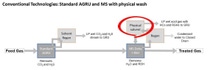

Due to its high solubility in methane, the removal of mercaptans from natural gas feeds pose a particular challenge. Once removed from the feed gas stream using a temperature swing adsorption (TSA) process, the mercaptans, along with other impurities, are removed from the adsorbent during the regeneration phase of the TSA cycle. Mercaptans do not easily condense out of the regeneration gas and can build up in the TSA system. To address this challenge, conventional approaches employ an expensive hybrid amine acid gas removal unit (AGRU) or equipment intensive physical solvent wash process.

BASF's Durasorb® LNG MAX technology can remove mercaptans from natural gas and provides an improved alternative to the conventional approaches.

Durasorb® LNG MAX offers alternatives to conventional approaches

Compared to the conventional approaches for removing mercaptans, Durasorb® LNG MAX technology simplifies the process. One of the conventional approaches to treating natural gas containing mercaptans utilizes a hybrid amine AGRU followed by a standard molecular sieve dehydration adsorption unit. Hybrid amines co-adsorb hydrocarbons, which are lost to the Sulfur Recovery Unit (SRU), resulting in a lost revenue stream for the operator. The Durasorb® LNG MAX solution with Durasorb® RSH adsorbent eliminates the need for a hybrid amine solvent in the AGRU process. A standard amine system is used instead, and the heavy hydrocarbons are passed to the Durasorb® LNG MAX where Durasorb® RSH selectively removes mercaptans and heavy hydrocarbons. This line-up results in a H₂S rich acid gas stream from the AGRU to the SRU.

Conclusion: Cost savings and increased efficiency with Durasorb® LNG MAX

BASF's Durasorb® LNG MAX technology proceeded by a standard amine AGRU offers a proven and cost-effective alternative to conventional technologies.

Thus, projects working to reduce CapEx could benefit from the simplified process line-up, which requires less equipment and provides a smaller footprint. BASF natural gas experts have decades of experience designing TSA units for removal of mercaptans from natural gas and rely on proprietary modeling software to design a unit capable of removing mercaptans, heavy hydrocarbons, and water to cryogenic specifications. With its broad portfolio of aluminosilicate gel materials that have been treating natural gas since the 1960’s, technical experts choose the unique combination of products to treat any gas composition.

We are happy to get in touch with you. Please feel free to ask questions or share your thoughts in the comment section below. You may also want to visit our website to learn more about us.

Durasorb® LNG MAX with Durasorb® RSH specialty mercaptan removal adsorbent eliminates the need for a hybrid amine, recovers a valuable hydrocarbon stream, and reduces the equipment required.

About the Author

Manish Mehta is a Technology Manager for BASF Adsorbents and Catalysts portfolio for Natural gas applications. Over the past 15+ years, he has handled various positions related to Design, commissioning, troubleshooting and product selection for both Solvent and Adsorbent based technologies in the Natural gas applications.

Manish is a Chemical Engineer by education from Thapar University India and has participated in authoring several technical papers and invention disclosures.

In his current role at BASF, Manish has been involved in Marketing, product selection and proposal management of BASF’s Sulfur Recovery catalyst and Natural gas Adsorbents portfolio for the Middle East, India, Central Asia and North Africa region.