X3D® Technology

X3D®: Shaping tomorrow's catalysts with today's technology

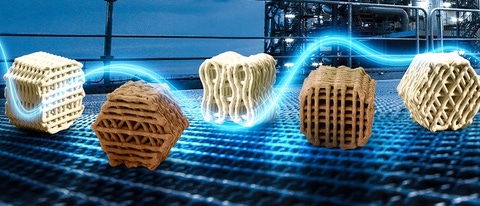

With our new X3D® technology, BASF expands its experience in catalyst production into additive manufacturing: Based on 3D printing, catalysts produced with our X3D® technology combine proven active materials with a new shaping technology. The result is a high reactivity, a higher freedom of catalyst design and a lower pressure drop minimizing energy consumption.

Key Facts

- Proven-track record in industrial plants since 2019

- BASF's sulfonation plant in Italy

- Versatile technology that can be applied to a wide range of catalytic materials

- Possibility to customize catalysts to customers’ specific conditions and needs

X3D® - Unlock Cost Savings and Sustainability

X3D® is a breakthrough shaping technology which will help you cut down costs and boost your sustainability goals:

Benefits of the X3D® technology come from intrinsic properties such a lower bulk density, improved mechanical stability, a faster prototyping, novel and tailored shapes, a lower pressure drop and improved geometric surface area.

We have successfully operated commercial plants using X3D® catalysts for several years, achieving remarkable results. This technology is poised to shape the future for both green and traditional value chains with unparalleled efficiency and improved speed-to-market.