Oxidation & Dehydrogenation Catalysts

Maleic Anhydride Catalysts

BASF’s Chemical Catalysts combine the strength of BASF – with the experience and expertise of our chemists and engineers.

Our maleic anhydride catalysts are valued components of the oxidation process for worldwide chemical manufacturing companies. BASF’s commitment to the maleic anhydride process and butane oxidation to maleic anhydride catalysts results in products and services that meet and surpass customer expectations and requirements.

Why BASF?

BASF is the only major producer of MA catalysts with:

- Own Catalyst R&D with lab and pilot scale production including performance testing at Ludwigshafen, Germany

- Own MA catalyst production at Ludwigshafen, Germany

- Own MA reference plants under different operation conditions (e.g., single pass, recycle mode)

- The excellent technical service from BASF is well known in the market from phthalic anhydride (PA) catalyst filling, start-up and customer contacts during operation. Additionally BASF further developed the new MA filling machines and ΔP measurement devices

Our latest innovation - the trilope-shaped MA catalyst

We commercially launched the trilobe-shaped Maleic Anhydride catalyst, helping to increase profitability for PBAT applications compared to the prevalent ring-shape catalyst.

It offers:

- a 1-2 percentage point higher maleic anhydride yield,

- a mild hot spot temperature minimizing plant shutdowns,

- an increased side crush strength for a 50% higher mechanical/chemical stability

- a 10% pressure drop reduction for lower energy consumption.

Meet us at the Annual Meeting of EPCA 2024 in Berlin to discuss our new trilobe-shaped catalyst. Or reach out to us today!

Technology

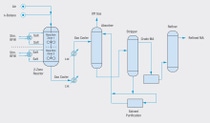

BASF’s n-Butane to Maleic Anhydride Process

Maleic anhydride can be produced by passing a C4 stream containing n-butane mixed with a large excess of air into a fixed-bed tubular reactor, where the butanes are oxidized to maleic anhydride with BASF maleic anhydride catalysts.

Research & Development

Innovation – New Processes, Technologies and Products for a Sustainable Future

Resource-efficient solutions and business models to decouple growth from the consumption of finite resources.

Our success factors include:

- Customer focus

- Digitalization

- Creativity

- Efficiency

- Collaboration with external partner

Full-scale pilot reactors for MA catalysts technology:

- Best possible quality control

- Most accurate performance measurements for new developments

- Directly measure real scale effects

- Global expenditures for research and development over € 2 billion, world leader in chemical industry

- Approximately 10,000 employees world-wide involved in research and development

- Around 950 new patents filed in 2020

- Global Know-how Verbund with external partners

Shanghai BASF Process Catalysis R&D Center

- Grand opening in 2019, dedicated R&D center for process catalysts and adsorbents research

- Development of catalysts and adsorbent solutions mainly for Asian Market

- Fast and timely support to our local customers, including BASF MA catalyst customers

- Catalysts characterization: ICP-OES, XRF, XRD, SEM/TEM, BET, XPS

- MA composition analysis: PMA, CMA, light ends, heavy ends analysis, through GC, GC-MS

- Raw material analysis: o-Xylene and naphthalene analysis through GC, GC-MS, AAS, CHNS/O analyzer

- MA production simulation and optimization

Product Portfolio

Publications

Where We Operate

Click on the map to see the locations of BASF’s research, sales and supply efforts for Maleic Anhydride Catalysts.

Seoul, South Korea

14-16F, KCCI Bldg., 39, Sejong-daero, Jung-gu,

Seoul, 04513, Korea

Dubai, United Arab Emirates

JAFZA One, Exit 17, Sheikh Zayed Road,

Dubai, United Arab Emirates

Mumbai, India

Mahindra World City, Chingleput Taluk,

Kanchipuram District, Tamilnadu

Ludwigshafen, Germany

Carl-Bosch-Straße 38,

67063 Ludwigshafen

Shanghai, China

NO. 300 Jiangxinsha Road, Pudong,

Shanghai 200137, P.R. China

Sao Paulo, Brazil

Avenida da Nacöes Unidas, 14.171

Torre Cristal – 15 andar

Säo Paulo, SP 04794-000

Al-Khobar, Saudi Arabia

3134 الامير نواف، Dammam 2nd Industrial City,

Dammam 34326, Saudi Arabia

Iselin, New Jersey, USA

25 Middlesex/Essex Turnpike

Iselin, NJ 08830-0770, USA