- Catalyst can be supplied in tablet, extrudate, ring extrudate and star extrudate form.

- Applicable for vapor or liquid phase Process.

- Commercially proven for dehydration of alcohols to olefins, e.g. ethanol to ethylene.

- Applicable for methayl amine, methyalaniline, fluorochemicals, hydrochlorination, cholosilane, silicon chemicals, etc.

Hydrogenation Catalysts

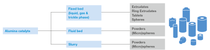

Alumina Catalysts

BASF provides the broadest selection of aluminum oxide catalysts and catalyst support materials in the industry. Each alumina catalyst in our portfolio is designed with its own carefully balanced combination of physical and chemical parameters, so that reliable catalyst performance and high productivity can be achieved within each of the diverse range of applications.

Dr.

Hans Donkervoort

Global Marketing Manager, Precious Metal Powder Catalysts

Alumina Catalyst Properties

Physical structure

- Typical surface area range from 50 to 350 m2/g

- Defined pore shapes and pore size distributions

Chemical composition

- Well-crystallized aluminum hydroxide raw materials

- On-purpose incorporation of promoters

Crystallinity and surface chemistry

- Various crystallographic modifications such as gamma and eta alumina

- Tunable surface activity via interplay of acid and basic sites

Catalyst shape

- Extrudates / tablets