Elevolve

ElevolveTM - High Performance Catalysts for Renewable Diesel and Sustainable Aviation Fuel

BASF offers advanced high-performance catalysts for the production of Renewable Diesel and Sustainable Aviation Fuel (SAF) using the most adopted production technology.

BASF's ElevolveTM portfolio offers cutting-edge catalysts designed for optimal conversion of bio-derived feedstocks, for example vegetable oils, animal fats, and biobased waste into top quality transportation fuels by using Hydrotreated Esters and Fatty Acids (HEFA) or Hydrotreated Vegetable Oils (HVO) production technology. These catalysts have been optimized to enable production of Renewable Diesel and Sustainable Aviation Fuel (SAF) at highest efficiency.

Improved selectivity combined with exceptional stability offers biofuel producers an opportunity to improve profitability of their plants by maximizing yields of Renewable Diesel or SAF.

Lower your costs with ElevolveTM

Production of renewable fuels is of growing importance as industries are looking to reduce emissions and become more sustainable. While production technologies with HEFA (HVO) are the currently dominant route, the adoption of sustainable fuels is highly affected by manufacturing costs. Lower production costs often imply that Renewable Diesel and SAF become more competitive. The selection of the proper catalyst technology is instrumental to optimize the manufacturing costs. If HEVA (HVO) technology is used to produce SAF, boosting selectivity towards SAF is critical to improve commercial competitiveness of the plant.

ElevolveTM HDI catalysts are there to help.

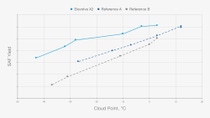

- Delta cloud point reduction of about 50°C is accessible with much lower yield loss compared to competitive catalysts.

- Extensive isomerization function of ElevolveTM HDI minimizes unselective conversion to gases and prompts selective conversion to SAF range hydrocarbons.

- ElevolveTM HDI catalysts stand out by showing an increased tolerance to impurities using a robust formulation.

Our Portfolio

Technology Background

The most adopted production technology for Renewable Diesel and SAF is referred to as HEFA (Hydrotreated Esters and Fatty Acids) or HVO (Hydrotreated vegetable oils).

Depending on the configuration of the plant, the process consists of one or two sections. The sour mode is frequently used to produce Renewable Diesel and is often seen as the most cost effective option if a switch to SAF is not required. A typical arrangement of the plant in a sour mode combines hydrodeoxygenation and dewaxing steps in a single reactor.

The sweet mode allows for more flexibility and enables production of either high quality Renewable Diesel or SAF. A typical arrangement includes two reactors with dedicated HDO and HDI sections respectively. As Hydrogen Sulfide is eliminated from the stream after the HDO reactor, this configuration enables using highly selective Platinum and Palladium based HDI catalysts that lead to enhanced Renewable Diesel or SAF yields.